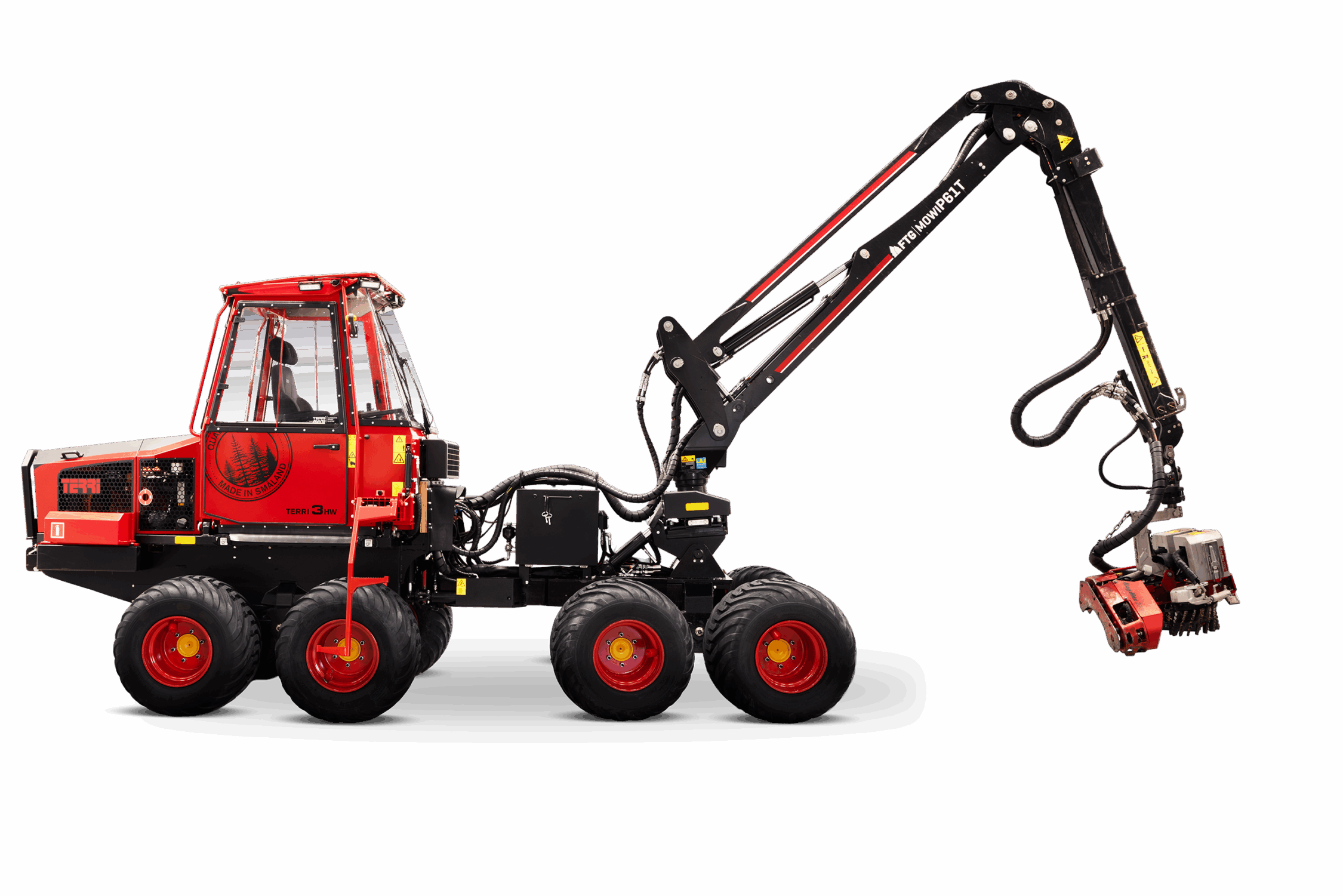

Terri 3HW

Terri 3HW is a powerful harvester designed for thinning operations where strength, precision and careful handling must go hand in hand. The machine combines high capacity with minimal ground impact and is built to perform reliably, day after day, in varying terrain.

Capacity and drivetrain

The engine is a 3.6-liter four-cylinder CAT delivering 75 horsepower and 318 Nm of torque at 1400 rpm. It is equipped with a particulate filter to reduce exhaust emissions and offers comparatively low fuel consumption per engine hour. The engine is approved for use with the renewable fuel HVO.

The hydraulic drivetrain with Terri’s AWS control provides smooth power transfer and strong traction in all conditions. With a tractive force of 88 kN and three gear ranges, Terri 3HW delivers excellent pulling power in forest terrain as well as efficient transport speed.

Stability and construction

The machine is eight-wheeled and built around an articulated center frame with a 45-degree steering angle. Each bogie is equipped with two hydraulic wheel motors, providing both strong traction and excellent mobility.

Terri’s low center of gravity contributes to high stability in uneven terrain or when working on slopes. The robust chassis and the eight driven wheels give the machine predictable behavior and a calmer operating experience for the driver.

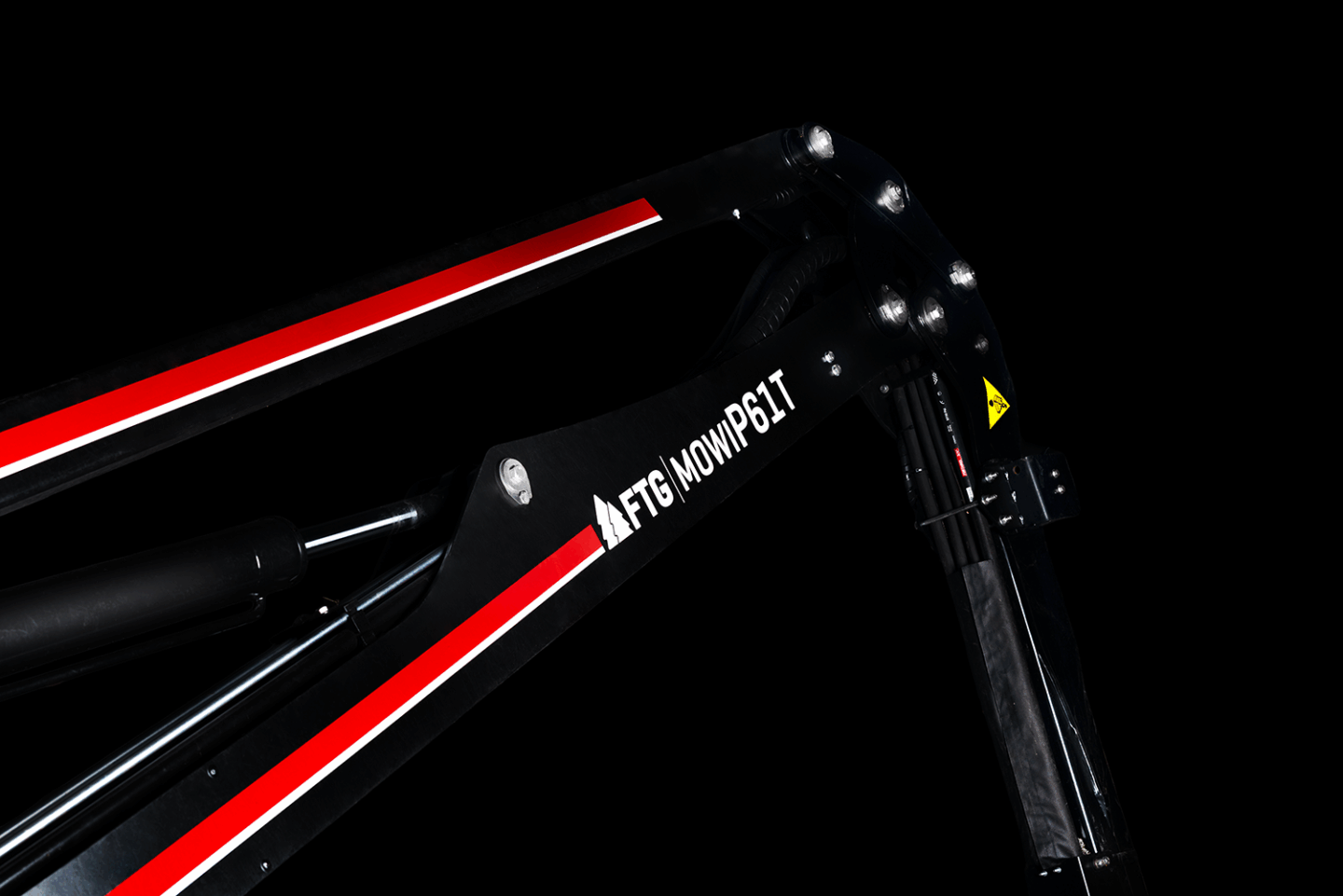

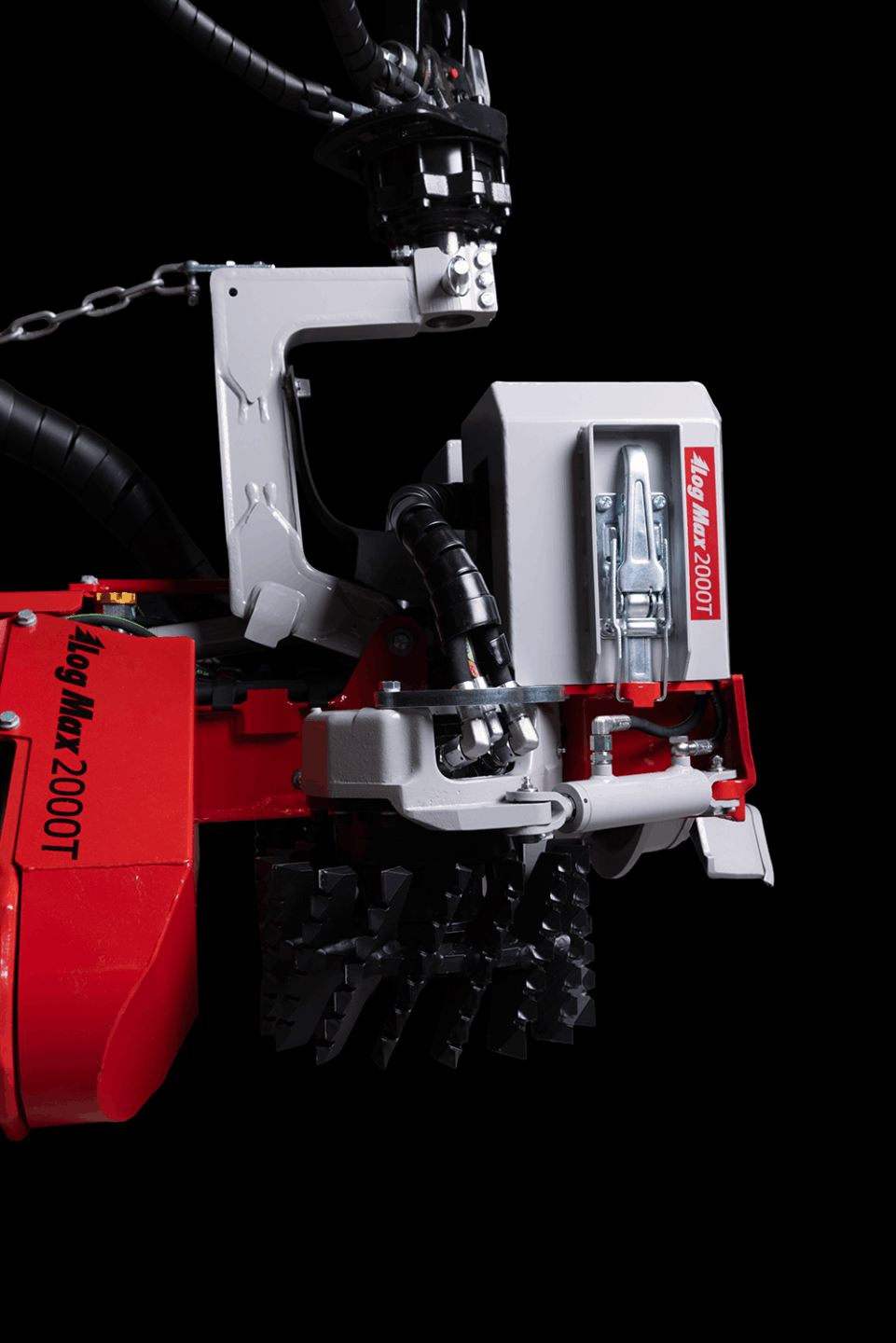

The harvesting module on Terri 3HW is equipped with crane tilt and a 7.5 m parallel crane. The harvester head can be fitted with stump treatment and color marking, and efficiently fells trees up to just over 40 cm in diameter.

Mobility and terrain performance

With 700 mm of ground clearance and eight 500/50 x 17 wheels, Terri 3HW goes where many others struggle. The combination of wide tires, balanced weight distribution and hydraulic bogie design allows the machine to move gently, even on soft ground.

The unique Terri AWS transmission system automatically distributes drive power to both the front and rear axles for optimal grip. When required, tracks or tire chains can be mounted for even greater traction and stability.

Active steering and proportional oil distribution provide smooth, precise movements even in narrow thinning corridors.

Operator environment and control

Terri’s spacious safety cab meets the latest standards and is mounted on vibration dampers to provide a comfortable working environment. It is well-insulated with low noise levels, and the elevated position ensures excellent visibility.

The operator’s seat is ergonomically designed, and the electrically braked, rotating seat base makes it easy to change driving direction. Joysticks and controls are integrated into the armrest for intuitive control of the machine, the harvester head and the crane.

The Dasa computer with color display provides a clear overview of the machine’s systems and enables personalized settings for each operator.

Dimensions and applications

The compact dimensions make the machine easy to maneuver even in dense thinning stands.

- Length: 5 928 mm

- Width: 2 050 mm

- Transport height: 3 100 mm

- Ground clearance: 700 mm

The agile design and solid construction make Terri 3HW a reliable tool for stand-based thinning and other operations where low ground disturbance and mobility are critical.

Frequently Asked Questions about Terri

-

Is it possible to apply tracks or skid protection on Terri's wheel driven machines?

You have the possibility to choose between tracks and skid protection. Here, in our product catalog, you can find all options.

-

What is Terri AWS?

The Terri AWS is a fully automatic solution that ensures optimal traction regardless of the terrain. It replaces the classic locking differential, and it presents a noticeable advantage on terrains that are steep or have poor bearing capacity. The system is sharper than the previous technology and it enables you to get more power out of each wheel. As a driver, you never need to decide if or when to switch on the AWS; everything happens automatically.

-

For which type of forestry are the machines best suited?

Terri´s machines thrive with first and second thinning and when driving on sensitive ground. Thanks to its first-rate range, it does a perfect job even when the terrain is uncompromising.

-

What is new on the latest machine Terri 3?

Compared to its predecessor, Terri 3 is upgraded with 20 innovations. These are for example updates in the cabin, in the design and under the bonnet. Fully automatic optimal traction (Terri Automatic Wheel System, AWS), stronger and more fuel-efficient engine and a 24-volt electrical system.

-

What does the machines designations stand for?

Terri 3 is the third generation Terri machine.

CW: combi

FW: forwarder

HW: harvester -

Where are the Terri machines built and developed?

The mastermind behind these forestry machines is Småland company Alfing i Älmhult. Almost all production takes place in a dedicated factory, which means shorter lead times and a high level of expertise in everything to do with the machines.

-

How can I buy a forestry machine from Terri?

Get in touch with your sales representative here on the website.

-

How can I adapt and customize my Terri machine?

Your Terri machine, your choice. We assemble your dream machine based on your requirements, needs, and wishes. We put you in the driving seat and provide you with masses of choices when it comes to cranes, comfort, and additional equipment.

Have a look in our Product Catalogue to see all optionals.